The Complete Guide to Metal Prints Created: Jun 10, 2024

When searching for a print lab to produce your prints, you can never be 100% sure you are getting the best possible results from your lab unless you can test all of the print labs in the world. When you print on metal, you are trusting that lab to give you a high quality print. If you are a professional photographer and sell your prints for a living, it is extremely important your lab is producing a high quality product that represents your brand. You want to be able to justify your selling price to your customers by knowing you’re giving them a print they can not only be proud to display, but to also know they are getting what they paid for.

Metal prints are extremely attractive and often produce stunning and attention grabbing results that make them extremely popular for photographers and professional artists, but how do you know if your lab is producing high quality prints? How do we know if a lab is taking all the necessary steps to produce the best prints possible? Even if you have a background or a good understanding of printing, it is really hard to know what separates one labs metal prints from another.

This article is to help inform and educate readers on what to look for in a lab to produce the best possible prints on metal. We hope you will choose Shiny Prints, but if you don’t here is a thorough look into what goes into printing on aluminum and how to best find a lab to purchase high quality metal prints from.

The Metal

For the absolute best quality, always make sure your lab is printing on chromaluxe HD metal panels. Always make sure they are using the 0.045” (about 1mm) thick, DOUBLE COATED panels and not their cheaper, thinner single coated product made by the same manufacturer. Some labs who are chromaluxe authorized labs use the cheaper single coated product because it gives them greater profit margins. As of the date of writing this article, there simply isn’t a better, higher quality panel to print on than chromaluxe. You can find an authorized Chromaluxe lab by going to their website (https://www.chromaluxe.com/where-to-buy/). Chromaluxe panels are the same panels being used for high end galleries, art shows and museums across the world. As of right now, they are the industry standard and unfortunately, there isn’t a close second. We have tested panels from Breathing Color and Duraluxe and the quality gap is too large.

Be aware that Chromaluxe sells defective panels to labs for a discount. These panels will contain defects ranging from small dimples and ripples to large dents. These are called “shop grade” or “dot material” panels and they are purchased by larger labs to maximize profit. Some labs will charge hefty premiums for “gallery” quality prints which are non defective panels. Do not fall for this practice. At Shiny Prints, we do not sell defective Chromaluxe panels to our customers and we certainly won’t charge you a premium to get the absolute best quality that can be offered.

How it is cut

Once you have taken the first step in finding an authorized Chromaluxe lab, you want to make sure the panels are cnc cut. A cnc machine is a computer controlled machine which uses router bits to accurately and effectively cut Chromaluxe HD aluminum panels. Many labs, especially smaller ones who only offer standard sizes, typically order their Chromaluxe panels in precut sizes. These labs typically do not offer custom sizes, however it is always a good idea to call and make sure the panels will be cnc cut. The reason why you want to have cnc cut Chromaluxe panels is because cutting these panels on a cnc machine not only produces a smooth, beautiful looking mirror finish, it also greatly reduces the chances of the print chipping and peeling at the edges. Avoid labs who cut their panels on a panel saw or a sheer unless they are doing a finishing pass on their cuts with a router. Another advantage is that panels cut on a cnc machine will always be square and exact in size.

The Printer

Moving on from the type of metal that is used, you want to make sure your lab is using the Epson F series line of dye sublimation printers to produce their prints. Until a few years ago, labs had to rely on converting inket printers to dye sublimation printers. Many labs are still using converted inkjet printers for their metal prints due to the extreme cost savings. Epson has changed the game when they released their dye sublimation line of printers that are specifically made for the HD Metal Prints process. The Epson F series line of printers produce the best possible prints on Chromaluxe by offering much sharper prints with a larger color gamut. We use the Epson F7200 in our facility as it is the largest F series printer in their lineup.

Any lab running an Epson F series printer should be using Epson OEM inks. Be careful about labs using aftermarket inks as these prints will not have the same sharpness, color clarity and fade protection that Epsons third party tested inks can achieve.

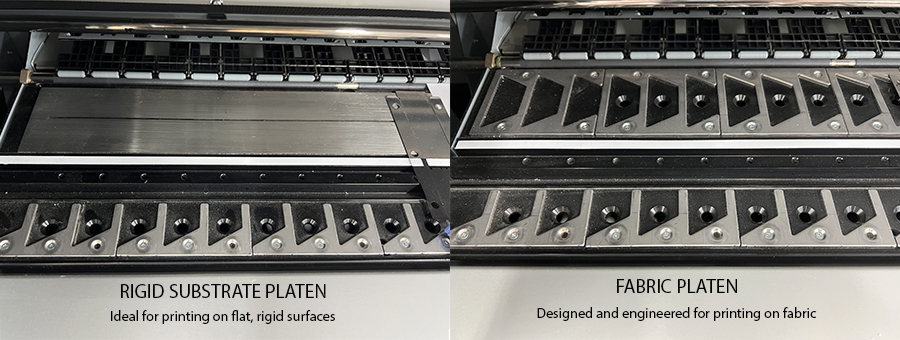

Another thing to look for, which may only be possible if the lab offers you a guided tour around their shop, is to see if they are using the flat platen for rigid substrates. This is something that is not included on Epson F series printers and needs to be specially ordered from a company that produces genuine parts for epson printers. The reason for this special platen is that the default platen installed is meant to be printed for fabric reproduction. Metal prints produced on this standard platen can have wavy defects in the prints especially when deep colors are used.

The Profile

The printer profile is where we really separate the men from the boys. Any high quality lab that caters to mostly professionals, will be having their own profiles custom made for their setup. Creating accurate printer profiles for the dye sublimation metal printing process is very complex and requires an experienced professional to handle. Given the high cost and complexity of having a custom profile made, most labs simply use the default profiles given to them, which are ok for printing some things, but when you’re printing fine art and subjects that require as much accuracy as you can, “ok” simply does not cut it. The dye sublimation process is very complex and has more steps involved than printing on other substrates. A properly made profile will produce a high quality printer profile that is tailored to suit a print lab's exact setup. The printer profile will be produced taking into consideration the exact type of transfer paper being used, the inks, the temperature and humidity of its environment as well as the time and temperature settings the panels are heated at. Any one of these factors are enough to cause a great shift in print results. Profiles must also be recalibrated every 6 months to compensate for normal wear on the print head or any other changes that may take place.

The Transfer Paper

Since the HD Metal Prints process is a 2 step process that uses dye sublimation, a lot of attention is paid to the kind of substrate being used and as a result, the type of transfer paper almost always goes unnoticed. Before being pressed on the heat press for transfer, photos are printed in reverse onto transfer paper which acts as the ink delivery system in this process. There are many types of sublimation transfer paper and a few that come highly recommended by distributors of Chromaluxe panels but we have found that the brands being pushed are typically the brands that specific retailer/reseller keeps in stock. We have tested every possible transfer paper until we finally found the best paper that works for us which is a transfer paper that is thicker and heavier than what is typically recommended for metal prints. The weight and thickness of this transfer paper cuts down on waving and banding during the transfer process as well as makes sure the transfers do not get wrinkled or creased with handling.

The Heat Press

The heat press a lab uses can also tell you a lot about a print lab. You want to make sure that your lab is using a pneumatic (air powered) heat press preferably a George Knight Triton or a SEFA subli or subliMAX. Typically, labs who offer metal prints up to a size 40x60 are using a George Knight MaxiPress. This press is suitable for metal prints no larger than 30x45”. While this heat press can accommodate a 40x60” print, we have found that it will not always apply even pressure throughout the entire size of the panel which often results in poor color transfer along the edges and especially the corners. We at Shiny Prints have a MaxiPress in house which we use for smaller prints and understand its limitations when it comes to larger prints which is why we only use our triton press for any prints larger than a 20x30.

Press Settings

Many labs, especially larger commercial ones will press the Chromaluxe panels at a very high 400 degree temperature for 2 minutes. This allows them to maximise production and get many orders done in a relatively quick turnaround. The problem with this, is this high temperature causes the coating which the inks absorb into to burn and leads to many potential issues such as blacks will turn slightly red, the coating is much more likely to crack, peel and chip at the edges. We at Shiny Prints use a low and slow method which results in much superior results as we press for approximately 10 minutes at a lower temperature to make sure your prints look the absolute best and stand the test of time.

Craftsmanship

Attention to detail is what we pride ourselves on here at Shiny Prints. All of our staff are extensively trained to look for any and all defects and to take every precaution possible to produce the best looking metal photo prints in the industry. Our obsession with quality does not stop with the quality and accuracy of our prints, they extend to the fabrication and application of all of our frame and mounting options. Our edge mounts and tuxedo frame options are always perfectly mounted flush to every edge of the frame. We have tested every lab that offers this option and nobody can replicate the quality that we offer. Our tedious process takes much more time and resources, but it ensures every print is a masterpiece.

The Hardware

We want our customers and our customers customers to have the best experience possible. We offer the absolute best hardware for hanging your prints at no extra charge. Our heavy duty hanging cleats are custom made to have a built in level. Our hanging cleat makes our prints the easiest to hang in the industry. Hanging hardware is one of the most overlooked items and it is where most companies cut corners. Do not settle for cheap, complicated hanging solutions, your hanging solution should be easy and efficient to use for a professional installation. For artists who require hanging wire to display their prints at shows and events, we also have this as an option, but do not worry, we will still also include our level cleat hanger system as well so you can use it at a later time when the print is ready for it's permanent home.

Packaging and Crating

Aluminum print panels are very thin and can get damaged very easily in transit if not packaged with proper protection. Shipping carrier handlers are not gentle with packages no matter how many handle with care or fragile stickers you place on the package. For our larger, more damage susceptible prints, we create the strongest wooden shipping crates in the industry. We understand the importance of having your prints arrive without damage. If your print does happen to arrive damaged, login to your account and submit a damage claim so we can process a replacement for you right away.

Support

Finally, you want a company that is going to support your business. At Shiny Prints, we work very closely with our customers and we are always looking for ways to be better. We only do metal and we do it better than anyone else. Being a specialty lab that only deals with one type of substrate allows us to give all of our attention to being the absolute best in our industry. When you call or email us, chances are you will be in contact with one of two of our owners. We are about you and your business because your business is our business and we greatly rely on the success of our customers. If you ever have any questions or concerns, please contact us using our contact us page and we will make sure your questions will be answered.

Automatic White Label Dropshipping

For all of our professionals, when you place an order where the shipping address is different from your billing address on file, we will automatically treat your order as a white label dropship to your customer. There will be no invoice and no identifying labels or names on the package or carrier label.